Gray iron casting process - cast iron parts

Gray iron casting process - HR foundry

Gray iron is the most versatile material for all foundry materials.

Gray iron casting has a high amount of silicone, which is responsible for the production of graphite when the alloyed materials are heated. The deflection of this graphitic microstructure gives the metal its gray appearance. By comparison, ductile cast iron production slows down the growth of graphite and allows the carbon to separate as spheroidal graphite particles instead.

The high carbon content is responsible for ease of melting and casting in the foundry and for ease of machining in subsequent fabrication. The low degree or absence of shrinkage and high fluidity provide maximum freedom of design for the engineer.

Through suitable adjustment in composition and selection of casting method, tensile strength of gray iron castings can be varied from less than 20,000 psi to over 60,000 psi and hardness from 100 to 300 BHN in the as-cast condition.

With subsequent heat treatment, the hardness can be further increased. However, component requirements should be carefully reviewed before specifying a higher strength and hardness grade of iron. An unnecessary increase in strength and hardness may increase the cost of the casting as well as increase the cost of machining through lower machining rates.

The casting process can have a significant effect on the structure and properties of gray iron casting.

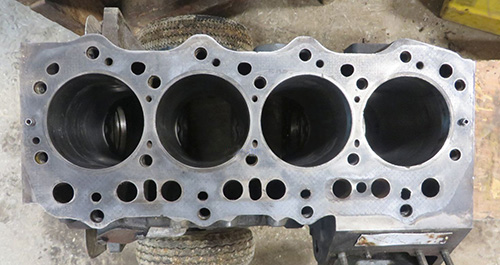

Green sand molding is frequently the most economical method of producing iron castings. Although castings up to more than 1,000 pounds can be made in green sand casting, it more generally is used for medium to small size castings. If green sand molds are not sufficiently hard or strong, some mold wall movement may take place during solidification, and shrinkage defects develop. For the larger castings, the mold surfaces are sometimes sprayed with a blacking mix and skin dried to produce a cleaner surface on the casting. This procedure is often used on engine blocks.

Gray iron casting is used in many market segments, including automotive parts, agricultural parts, machinery and building parts, electronics parts, irrigation parts, ventilation parts, architecture parts, construction parts and transportation industries