Introduction to steel casting valve body

Steel casting is a specialized form of casting involving various types of steel. Steel castings are used when cast irons cannot deliver enough strength or shock resistance. China steel casting.

Examples of items that are steel castings include: hydroelectric turbine wheels, forging presses, gears, railroad truck frames, valve bodies, pump casings, mining machinery, marine equipment, turbocharger housings and engine cylinder blocks.

Steel castings are categorized into two general groups: carbon steels and alloy steels.

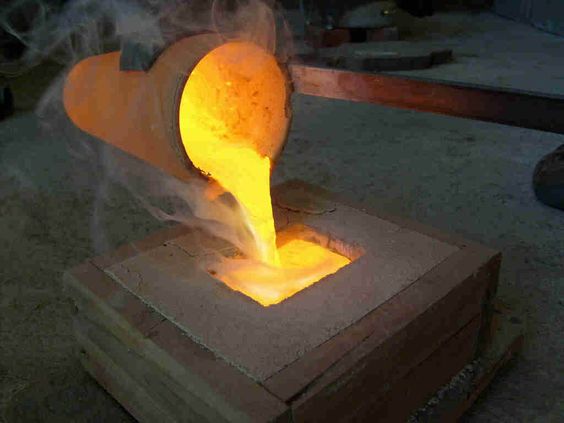

Steel casting is more difficult to cast than cast iron. It has a higher melting point and greater shrinkage rate, which requires consideration during mold design. Risers should be given more capacity to draw from as the metal cools and shrinks. Attention should be paid to the thickness of mold cavities, as thinner areas will cool quicker than thicker areas, which can create internal stress points that can lead to fracture.

Molten steel is also less fluid than molten iron, making it more difficult to pour and fill intricate gaps in a mold cavity. Molten steel is also more likely to react with internal mold surfaces, making for more unpredictable results.

Cast parts often require machining to achieve accurate tolerances and desired surface finishes. Carbon steel is the easiest type of steel to machine. High-carbon steel can be more time consuming to cut or grind, and will wear tools faster. Low-carbon steel can get gummy, making it difficult to work with.

Generally, the presence of alloys used to increase mechanical performance often make machining more difficult.